What are the Benefits of Using Protective Film in my Industry?

You've just acquired your brand-new car, filled with excitement as you prepare to drive off the lot, only to notice a significant scratch stretching down the side. The critical oversight? The absence of protective film.

Protective film has consistently served as the enchantment that escorts your pristine new cars from the manufacturing plant to the dealership's display.

For numerous years, NB Technology has been revolutionizing protective film, crafting tailor-made pieces to shield vehicles, devices, and more.

Upon delving into the advantages within the industry, you'll gain insight into how protective film safeguards vehicles and various surfaces from the everyday wear and tear associated with regular use.

What is Protective Film?

Protective film is a material that protects surfaces that are susceptible to damage: minor or moderate abrasions to scratches and more.

Protective films were originally developed with military applications in mind.

What Constitutes Protective Film?

The composition of protective film varies based on its intended application across different purposes and industries. The materials commonly employed in crafting protective film, primarily plastic, are diverse:

1. Low-density polythene films: These films boast heightened elasticity and flexibility while maintaining a low weight.

2. Polyvinyl chloride: Sleek in nature with relatively elevated elasticity, it proves to be an ideal choice for protecting metal surfaces.

3. Polypropylene: Known for its firmness, even in higher temperatures, making it a suitable option for certain applications.

4. Polyolefin: Particularly effective for use with glass or painted metal, with specific variants tailored for packaging purposes.

5. Co-extruded, low-density polythene: This type of film employs layering techniques, providing a higher level of protection.

6. Paper: Generally utilized to guard against very low-impact damage.

Understanding the specific properties of these materials enables the creation of protective films tailored to meet diverse needs and challenges.

Types of Protective Film

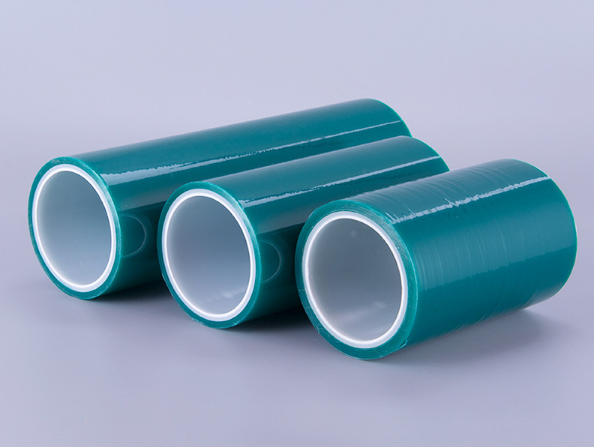

Protective films come in a variety of styles, each tailored for specific applications, and generally differ based on thickness, material, and adhesive strength.

Two prevalent types of protective films include:

1. Surface Protective Film:

A high-quality surface protective film is easily applicable and removable, imparting a sleek finish to the surface it safeguards. It serves as a shield for vulnerable surfaces such as glass, commercial glazing, plastic, stone, brick, granite, marble, and more. Industries emphasizing the manufacturing and distribution of packaged products often require this form of protection. However, cutting the film to fit diverse surfaces poses a challenge, and minimizing bubbling during application often demands professional expertise in surface protection films.

2. Protection Film for Painted Surfaces:

Paint protection films exhibit heightened resistance to impacts. Variants like clear paint protection film (PPF) possess "self-healing" properties, reverting to their natural shape after impacts or abrasions. Typically made from elastomeric polymer, these films are nearly invisible, preserving the object's aesthetic appeal while offering protection. Common applications include cell phones, electronics, cars, airplanes, and various equipment. While not impervious, PPF provides superior defense against rock chips and environmental contaminants. It is also chemical-resistant, enabling equipment cleaning without concerns about adhesive loss or hindrance in maintenance practices.

What are the Benefits of Using Protective Film in my Industry?

Protective film applications are varied and nearly limitless. However, in the aerospace, electronics, industrial, automotive, medical, and defense industries, protective film can be especially crucial to functionality.

In the following industries, the protective film offers benefits such as protection from scratches and abrasions, shielding against humidity and dirt, resistance against hot or cold temperatures, UV resistance, and chemical resistance.

ELECTRONICS

Electronics, such as mobile phones and other hardware, are prone to physical damage, especially screen damage. There are diverse applications for protective film in industries like television manufacturing, electronic shipment, and similar businesses.

INDUSTRIAL

Industries, in general, widely employ protective film, often necessitating customized pieces to fit equipment or newly manufactured products. Products in transit to distribution centers or warehouses can incur significant damage, making protective film crucial.

AUTOMOTIVE

From wheels and doors to fenders and bumpers, comprehensive protection is essential for cars. Protective films offer an excellent solution for overall surface protection without compromising the aesthetic appeal of your vehicle.

MEDICAL

Medical devices are typically expensive and require meticulous maintenance to prevent metal corrosion. The addition of a protective layer helps forestall premature wear and tear, ensuring the smooth operation of the machines.

Which Protective Film Should I Choose?

To make the appropriate choice for your needs, consider the following factors:

1. Longevity: Opt for a high-quality, branded film that guarantees durability. Installing a cheap film that deteriorates within a few months is counterproductive.

2. Warranty: Choose a product with a reputable customer care system and attractive warranty offers. For instance, Pregis PPF typically provides up to ten years of warranty, making it an excellent choice for long-term use, especially in equipment like cars.

3. Quality: Material plays a crucial role in determining the quality of the film. Ask questions about the material to ensure it meets basic requirements such as scratch resistance, abrasion resistance, and UV protection. While quality may be influenced by your budget, it's generally possible to obtain high-quality films at reasonable prices.

4. Application: The application or installation of protective film can be challenging, especially for those without experience. Consider hiring an expert to ensure a bubble-free surface. This is particularly crucial for achieving optimal results and maintaining the integrity of the protective film.

If you have a protective film application, your next step could be finding a converter who meets your particular needs. At NB Technology, we pride ourselves on being able to deliver highly customized parts that fit the particular needs of your product and application.